1-Minute Summary

- Pick a lab with an ISO 17025 scope that matches your matrix/analyte; use LAAF when your analyte is active on FDA’s Dashboard.

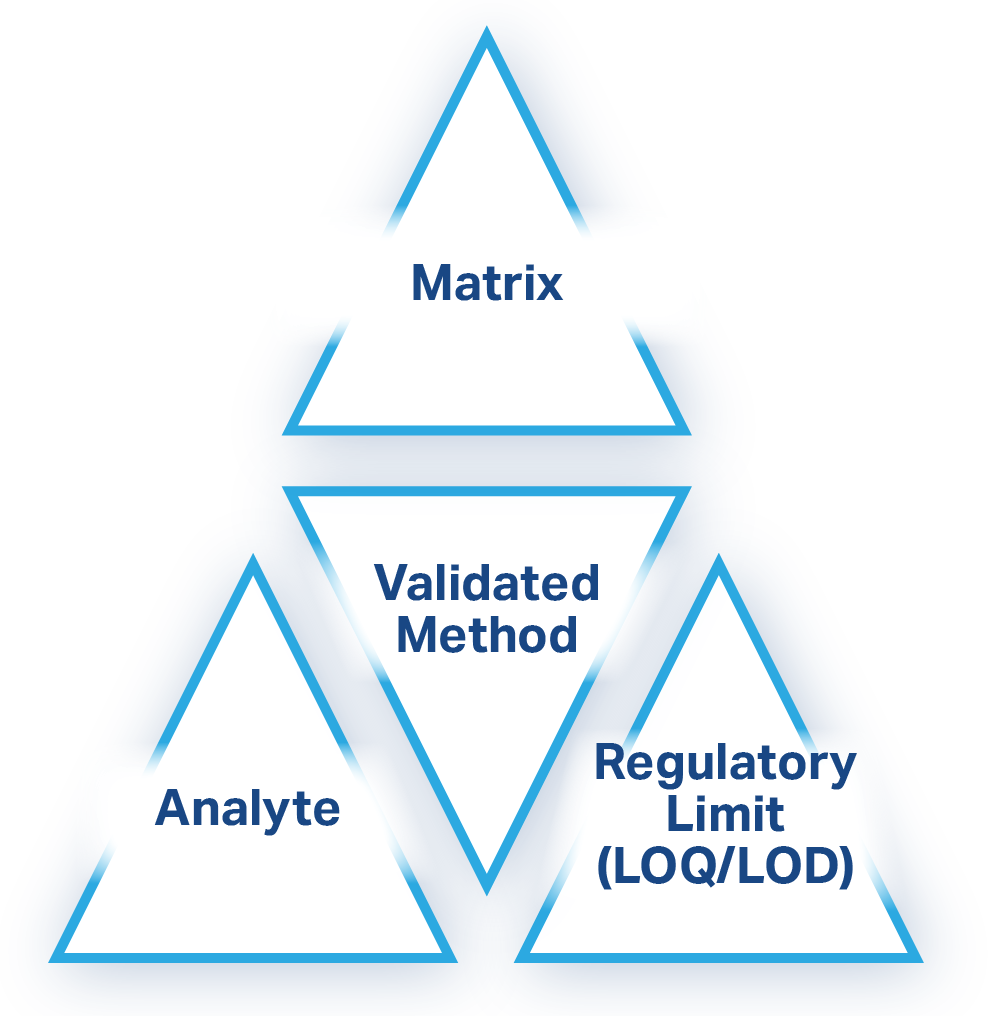

- Require validated, matrix-appropriate methods, with LOQ/LOD below the limit and full QC so results are defensible.

- Protect sample integrity (after-arrival sampling, chain of custody, temperature control) and plan realistic turnaround.

- Deliver a complete PLAP and upload via FDA ITACS – clear filenames, entry/line mapping – to avoid preventable rework and delays.

A Qualified FDA Detention Testing Lab Helps You Avoid Costly Mistakes

If your shipment requires FDA detention testing, the lab you pick can make or break your submission.

FDA reviewers move faster when your package is complete and defensible. A lab experienced in FDA detention testing and FDA ITACS submissions helps you avoid preventable rework and delays. Use this guide to choose a lab whose results the FDA is more likely to accept the first time.

For a deeper walkthrough, watch our webinar: What Do I Need to Know About My Testing Lab?

1) Accreditation that Counts (ISO 17025 vs LAAF)

- ISO 17025: Confirm the scope matches your matrix and analyte (not just “food” in general). Ask for the ISO certificate and the scope page that lists your product type/analyte.

- LAAF: Use a LAAF-accredited lab when your analyte is active on the FDA’s LAAF Dashboard for import testing. If LAAF isn’t mandated, ISO 17025 with correct scope is typically acceptable.

- Check the FDA’s LAAF Dashboard for current analyte groups and compliance dates. Currently, the FDA requires using a LAAF-accredited lab for three Analyte Groups (Listeria, Melamine, and Mycotoxins).

- Certified Laboratories’ Melville, N.Y., and Turlock, Calif., laboratories hold LAAF accreditation (see LAAF-Accredited Laboratories listing).

2) FDA Detention Testing Labs that use Validated, Fit-for-Purpose Methods

- Methods should align with FDA or recognized compendia (e.g., FDA BAM, AOAC, USP, EU SANTE) for your matrix.

- Confirm the method ID/version, matrix ruggedness, and any documented deviations.

- Require supporting QC and validation evidence (recovery, selectivity, calibration model, precision).

- Red flag: House methods or validations done on a different matrix; this carries high risk of rejection.

3) Sensitivity & Reporting (LOQ/LOD, Units, Uncertainty)

- LOQ/LOD at or below the regulatory/action level for your hazard.

- Report in the correct units (ppm vs mg/kg; CFU/g vs MPN/g).

- Ask for measurement uncertainty and note any dilution factors.

- Red flag: “ND < LOQ” when the LOQ is higher than the limit –the FDA can’t use it.

4) FDA Detention Testing Labs that Follow FDA Sampling Guidelines

- Does the lab follow FDA sampling guidelines?

- Confirm after-arrival sampling when required and maintain chain of custody from port to lab.

- Verify the Notice of Action (NOA) details – entry numbers, line items, lots, product codes – to ensure the correct goods are sampled.

- Capture photos during sampling, label cartons clearly, complete the collection report, and re-verify all identifiers at the lab.

5) Defensible Reporting & PLAP Submission

- A complete, defensible report includes: method summary, QC results (blanks/spikes/duplicates and pass/fail), LOQ/LOD, units, uncertainty, analyst/signatory credentials, dates, instrument IDs, and traceable sample IDs.

- Keep raw data on hand in case FDA asks.

- Build a tidy PLAP (report + method/QC appendix + COC + photos + entry/line cross-reference) and upload via FDA ITACS with clear filenames.

FDA Detention Testing Lab Quick Checklist

Here’s what to ask your lab when planning FDA detention testing:

- Accreditation – Is the lab ISO/IEC 17025 accredited and FDA-recognized?

- Scope – Can the lab test all FDA-targeted analytes (antibiotics, pesticides, colors, allergens) for your matrix?

- Methods – Are methods validated (FDA, AOAC, EU SANTE) and matrix-specific?

- Sensitivity – Do LODs/LOQs meet FDA action levels?

- Turnaround Time – How fast can results be delivered to avoid shipment delays? Do you offer rush TAT options?

- Quality Controls – Do you run spikes, blanks, duplicates, and proficiency tests?

- Reporting – Are reports formatted for FDA acceptance and regulatory defensibility?

- Support – Will you help with Import Alerts, DWPE removal, and corrective actions?

Certified Laboratories: 60+ Years Combined Experience with FDA Detention Testing

- Many former FDA employees across our network.

- Testing done using FDA-accepted methodology.

- Ability to expedite the release of detained products.

- Nationwide sampling – we can help you no matter what port you use.

- Experience working with importers and overseas processors to overcome FDA detentions through the 766 process (reconditioning).

- Red List removal and U.S. Agent services via EAS Consulting Group, a Certified Group company.

If you need FDA detention testing, one call handles it all when you choose Certified Laboratories. We can help you with sampling, testing, and FDA submission – coast to coast, start to finish!