Shelf Life / Stability Studies

Shelf-life testing provides objective measures as to a product’s quality and stability after production. The study results enable manufacturers to determine optimal storage conditions, packing systems and to set expiration and “best by” dates based on microbial, chemical and physical metrics and correlated sensory degradation.

Accelerated protocols increase the level of one or more storage factors such as temperature, humidity and light in order to extrapolate for real-time results. Product quality is measured at specific sampling rates via accelerated conditioning chambers. Accelerated protocols can yield results up to four times faster than standard shelf-life testing.

Certified Laboratories is a leading laboratory for shelf-life studies. With 32 laboratories in the U.S. and Canada, our experts support testing for a wide variety of products.

Examples of Types of Shelf-Life Tests:

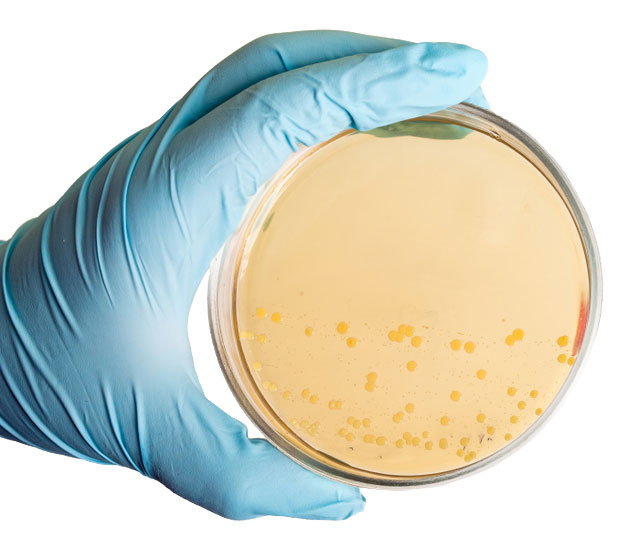

There are four main areas of shelf-life testing: microbiology, chemical, physical, and organoleptic. The specific area of focus for any shelf-life study will change depending on the probable driver of shelf-life. For example, a low moisture product with relatively high fat and oil composition will focused on chemical and physical testing, whereas a non-sterile, high moisture product would be focused on microbiological spoilage.

Time-temperature integration

Accelerated modeling for oxidative rancidity, vitamin degradation, moisture content change, etc.

Microbial stability studies

Challenge study testing for pathogens and/or spoilage organisms

Shelf-life Testing Can Determine:

Mold growth

Moisture gain/loss

Vitamin loss

Color loss

Adsorption of undesirable flavors

Oxidative and hydrolytic rancidity

Microbial driven degradation

Sensory / Color / Flavor quality changes

Protein denaturation (toughening)

Textural changes

Emulsion breakdown and phase separation

Ready to get started?

Contact Certified Laboratories today to discuss your products and testing needs. We look forward to working with you and showing you why we are the choice for a dedicated testing partner.